Case Study:

MIRROR MOUNT FOR DEFENSE TARGETING SYSTEMS

Challenges

Mirror Mount For Defense Targeting System:

- Very tight tolerances

- Flatness and bearing journal alignment

- A lot of material removal

- Nonsymmetrical part

- Prior efforts resulting in stress relieving and part deformation

Project Summary

Mirror Mount For Defense Targeting System:

This part had multiple challenges for the following reasons.

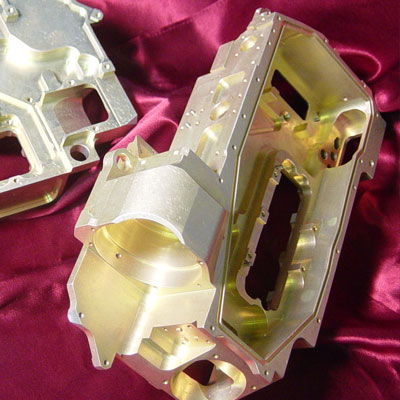

Overall length 16’’ x 5.00 Diameter

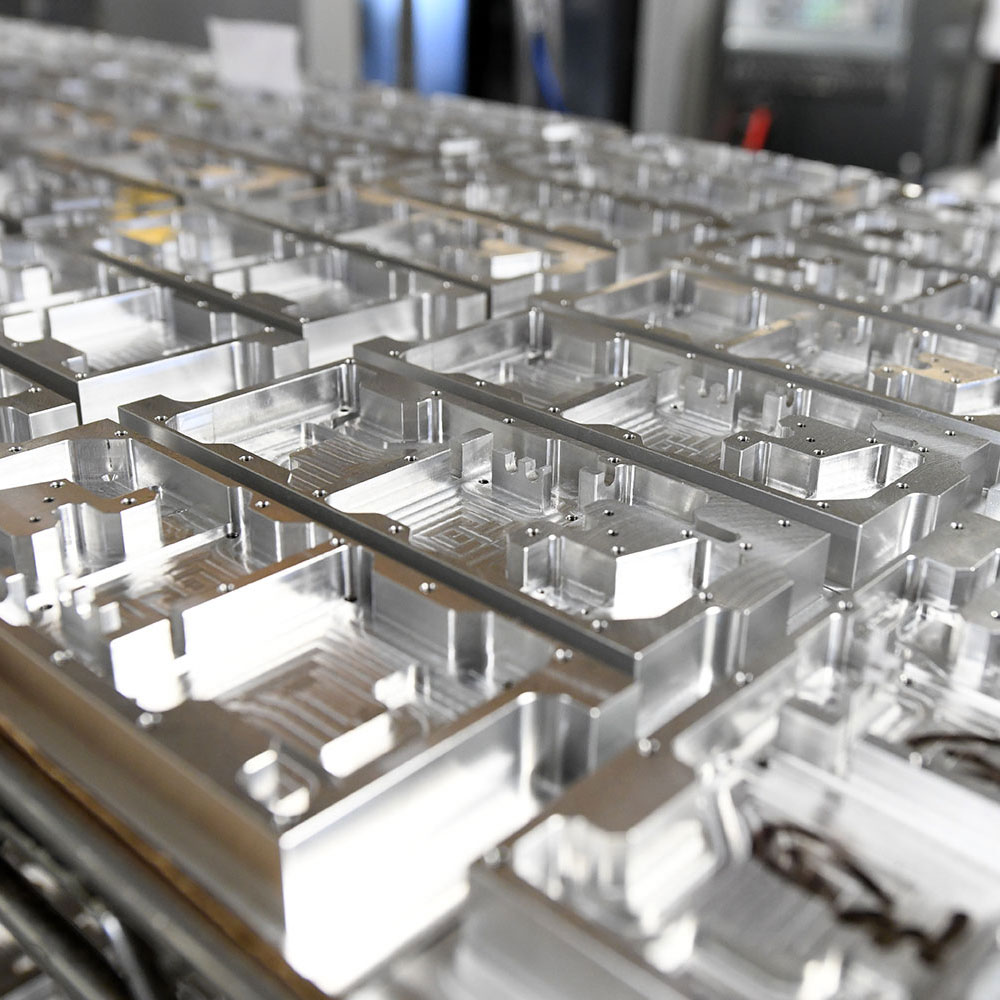

The part was designed to be cast aluminum with only the critical features left for machining, however due to the qty ordered (400 pcs) the customer agreed to solid billet which introduced other challenges.

There was a fair bit of stress relieving from removing large amounts of material and the part being non-symmetrical in shape.

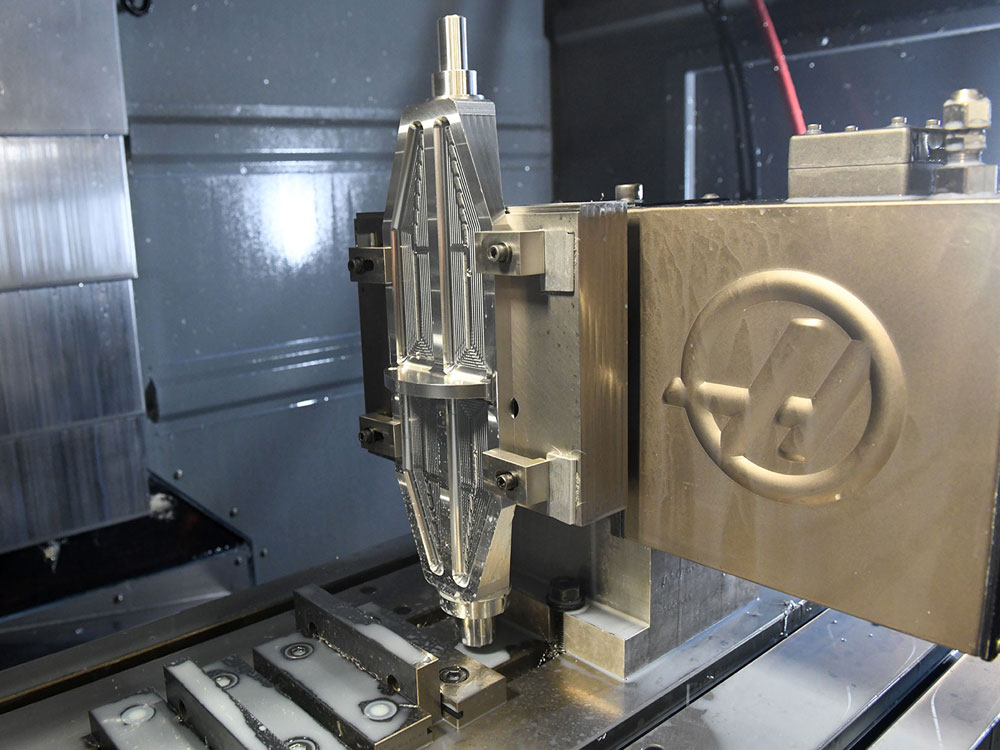

Rough machining was required along with stress relieving heat treat before final machining. The bearing journals required very tight concentricity of .0005 as well as .0002 OD tolerance and the large flat mounting surface required a flatness within 0.001” across the part.

We intended to turn the journals between centers however the tail stock pressure was too great and pre-constrained the part causing deformation once released in the free state. The final solution was to fixture the part onto a rotary table without pre-constraining the part, this allowed us to OD machine the bearing journals with precision boring heads and maintain the concentricity requirement.

There was a total of 10 machining operations to complete the process.

WHY CHOOSE JET HELSETH MANUFACTURING

Since 1995, JET HELSETH Manufacturing has been specializing in precision manufacturing services to customers in the defense and aerospace manufacturing industries across North America.

Our continued growth and over 25 years of business is a testament to our success and why customers continue to partner with Jet Helseth Manufacturing.

ONE SOURCE SOLUTION

JET HELSETH offers end-to-end services, meaning that we handle the entire process from start to finish. We typically handle raw material sourcing, all manufacturing processes, including heat treating, plating, finishing, marking, mechanical assembly and testing if needed. Special Packaging requirements, or delicate or large parts, no problem, we’ll design and build custom packing or crates to ensure that the product arrives at your destination undamaged. Keeping the entire process under one roof reduces costs and complexity of the project for the customer.

ON TIME DELIVERY

U.S. based manufacturing and supply chain. JET HELSETH uses the most advanced manufacturing tools and we bring our manufacturing expertise to your products. Have your product made quicker, better & easier than ever before.

QUALITY ASSURANCE

JET HELSETH has a fully staffed and equipped Quality Assurance Department in place and confidence that we consistently meet or exceed our customer’s needs for quality & security. Our certifications and standards include: ISO 9001:2015, NIST:800-171, ITAR, and more.

ADVANCED CAPABILITIES

The experience provided by JET HELSETH will fill in vital knowledge gaps to help you find niche and innovative design solutions within your industry. Whether you need advanced capabilities, innovative CNC machining, or exotic materials used in the Defense & Aerospace industries; JET HELSETH can help you refine the design and/or manufacturing process.

COMPETITIVE PRICING

The main advantage of working with JET HELSETH is we streamline production, and this, in turn, leads to cost savings and fewer headaches. Working with a manufacturer that understands your industry and removes all of the manufacturing obstacles you’d normally face, results in a competitive pricing advantage for your business.

SMALL TO LARGE VOLUMES

JET HELSETH negotiates competitive prices on bulk raw materials, and this keeps costs low even as production increases. This means that if you start off small (let’s say a limited run of 100 components), you can immediately scale up production without incurring significantly steeper costs.

OUR CORE SERVICES

We provide our customers a “total solution” from engineering support, manufacturing, assembly, to finishing services that include heat-treating, plating, sand blasting, and anodizing.

JET HELSETH MANUFACTURING INC.

1730 Patterson Ave. Deland FL 32724

(407) 324-9001

JET HELSETH is an AS9100D and ISO9001:2015 Registered facility. Established in 1995, our leadership team possesses over 100 years of precision manufacturing and quality engineering experience.