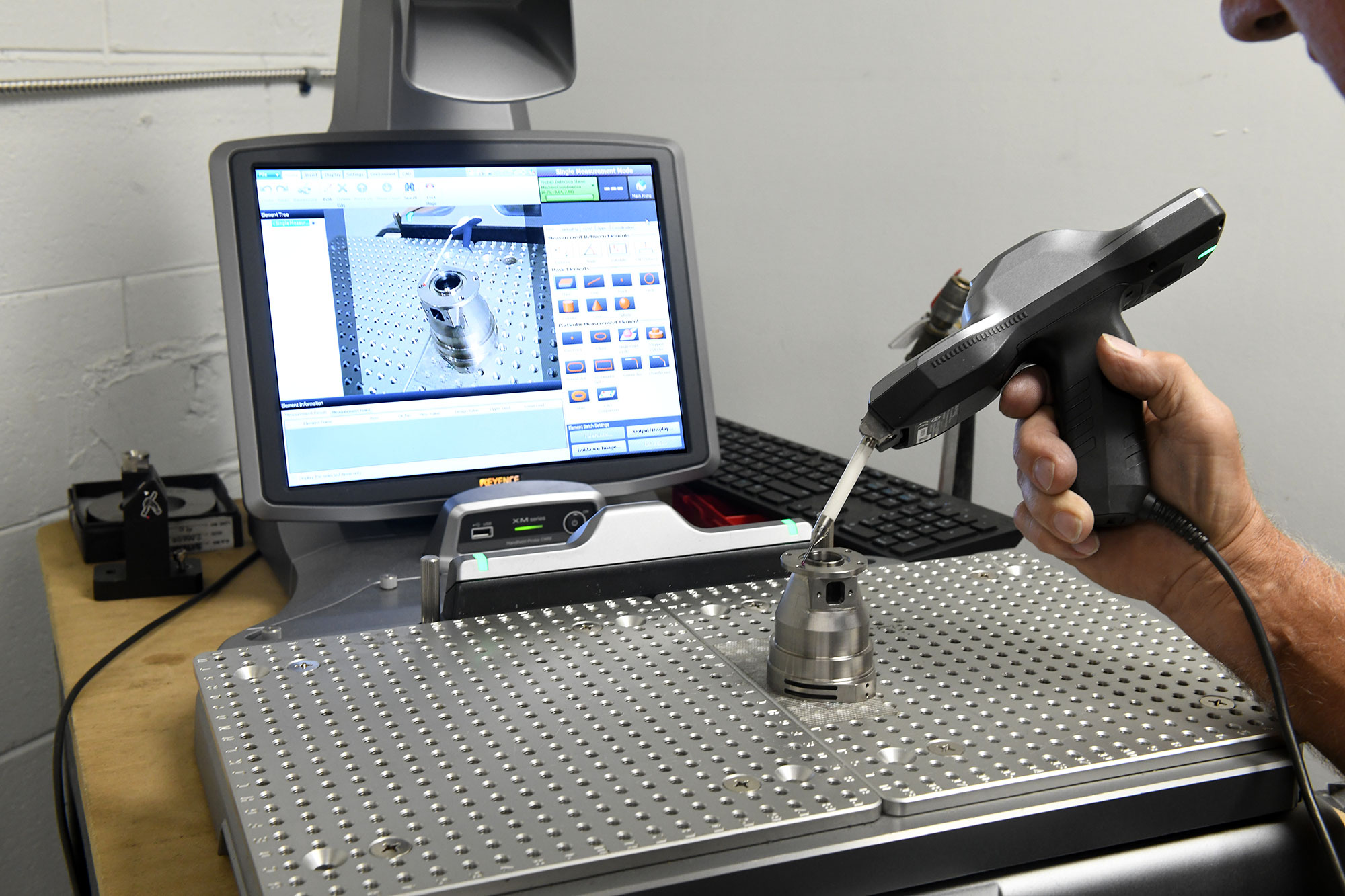

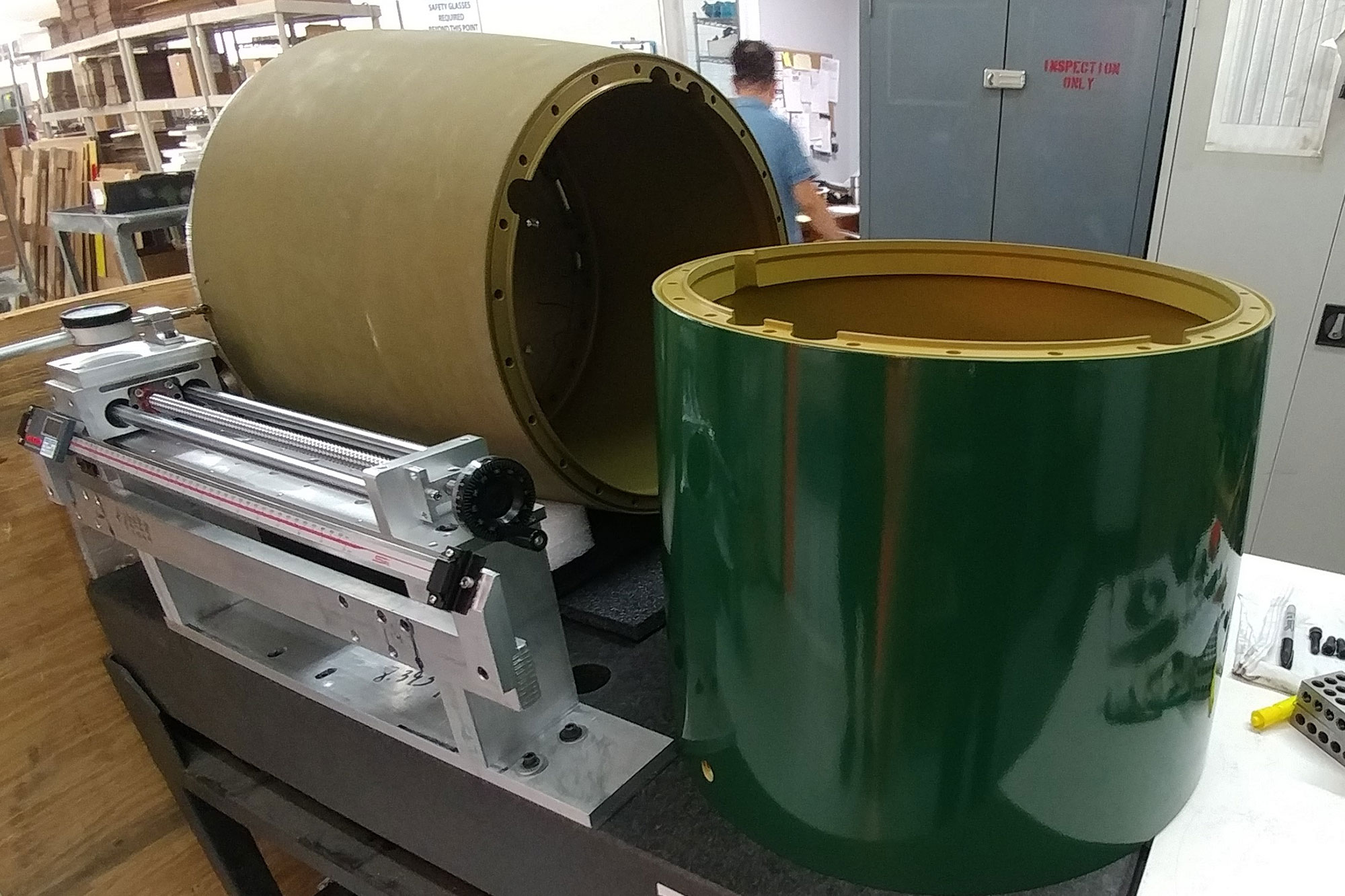

INSPECTION & TESTING

JET HELSETH has a fully staffed and equipped Quality Assurance Department in place utilizing a quality system based on ISO 9001:2015 requirements to ensure that we consistently meet or exceed our customer’s needs.

Testing operations include:

Electromechanical testing (power supplies, digital O-scopes, functional test fixtures, Torque data logger) of mechanical assemblies. Mechanical force/load and pressure testing of parts, assemblies and housings. Test procedure and reporting. All of our inspection equipment is traceable to NIST standards.

F.A.I.R. – First Article Inspection Report – Our First Article Inspections are performed on AS9102 Rev B format. We use DimExpert software for drawing annotation.

- ISO 9001:2015 registered Quality System in place

- 5S Production Operation

- Certified Small Business – SAM/Cage Code: 1FUT6

- ITAR Registered

- Cyber Security compliant to NIST:800-171

- Certified for Model Based Machining by Lockheed

Inspection equipment includes surface plates and measurement indicating tools certified and traceable to NIST standards including height gages, gage blocks, micrometers, gage pins, a large inventory of plug and ring gages, assorted Deltronic Pin Gages, optical comparator, Brown and Sharpe Micro-Hite, Starrett Super-Mic, and a Brown & Sharpe Coordinate Measuring Machine.

JET HELSETH MANUFACTURING INC.

1730 Patterson Ave. Deland FL 32724

(407) 324-9001