FINISHING DEPARTMENT

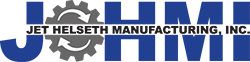

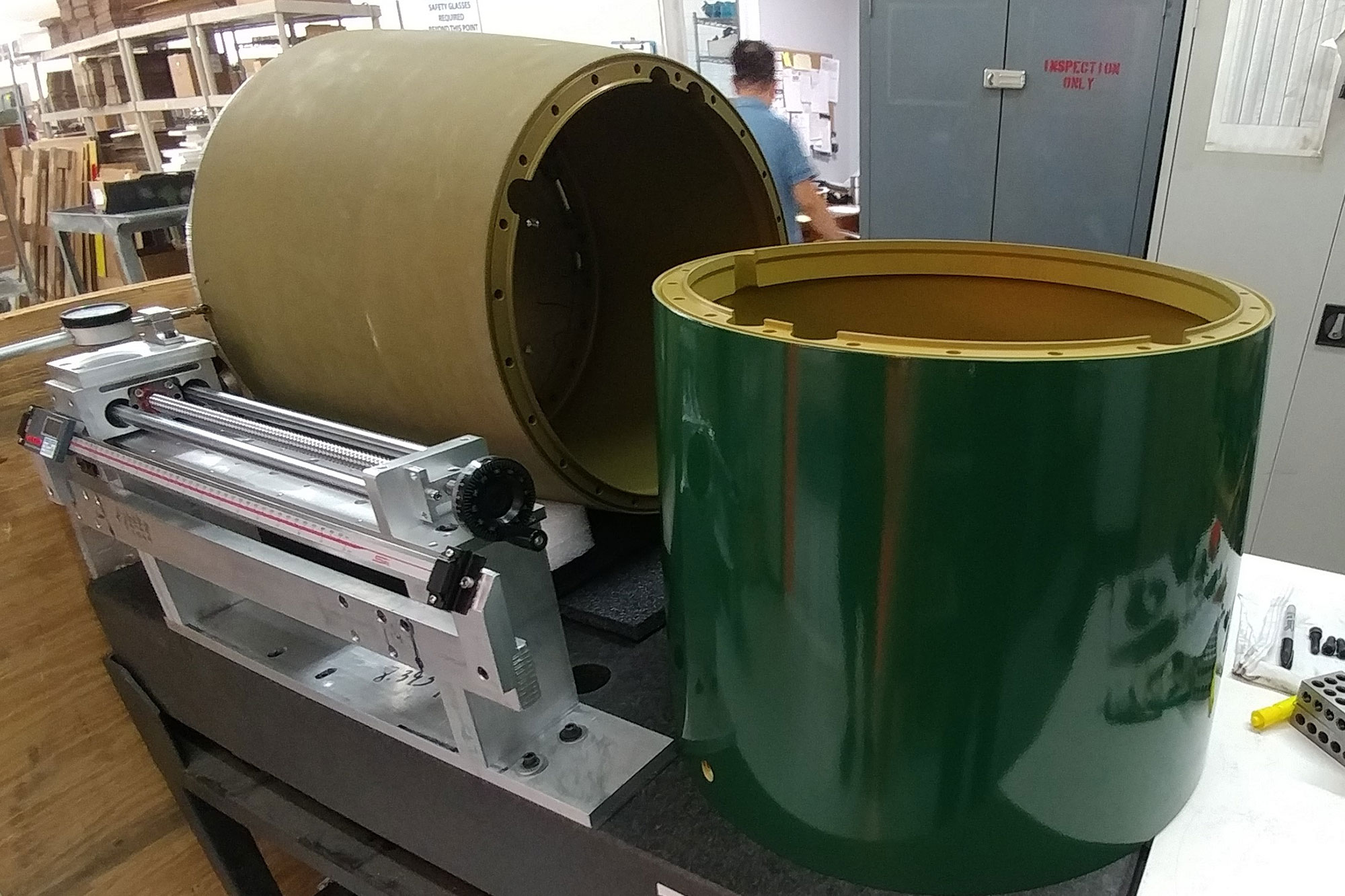

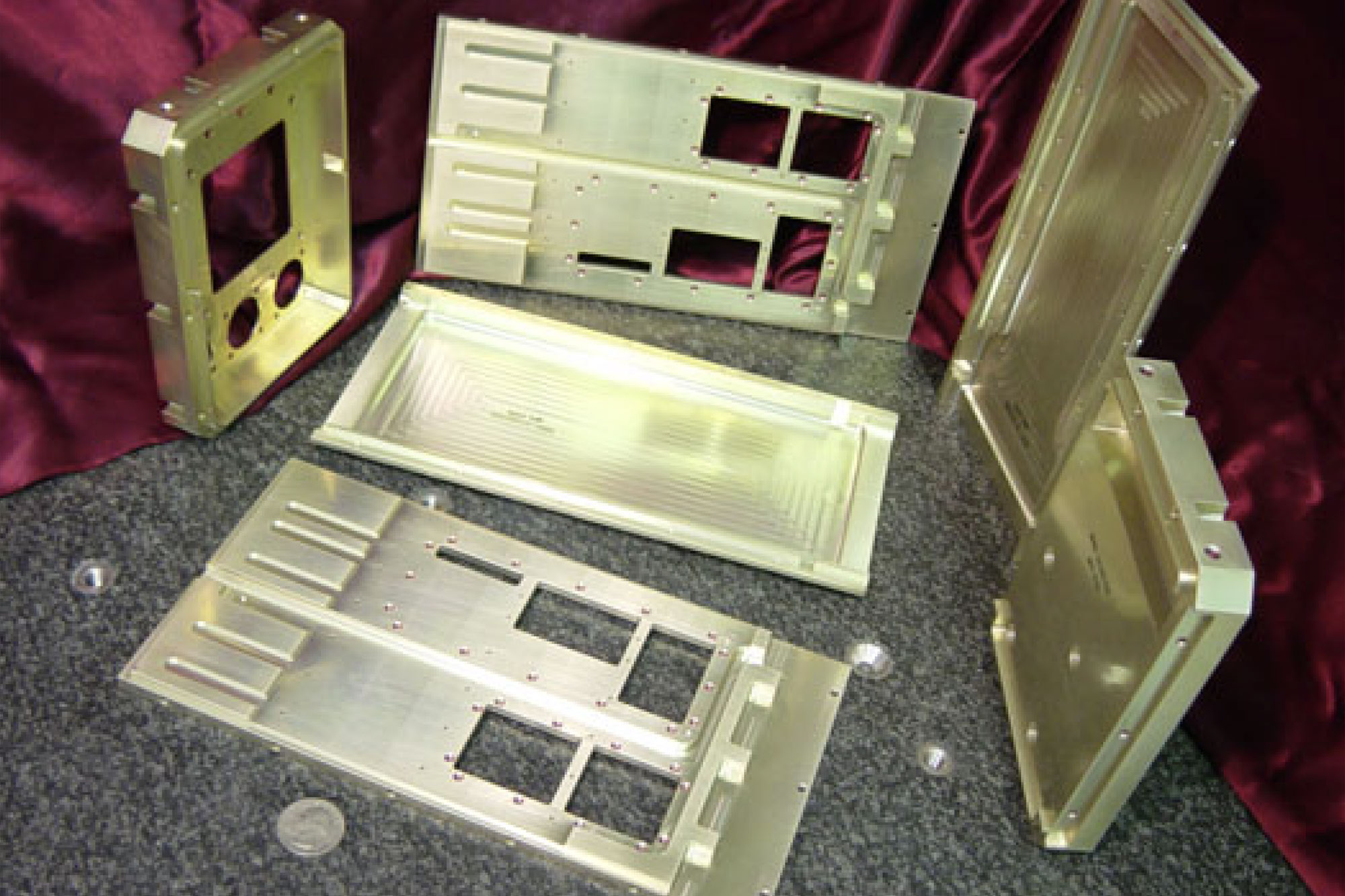

JET HELSETH has a fully equipped and staffed Finishing Department with small & large tumbling/deburring processes, glass bead and grit blasting processes, deburring tools, rotary files, and other equipment to support the quality finishes required on our projects.

Core finishing services include:

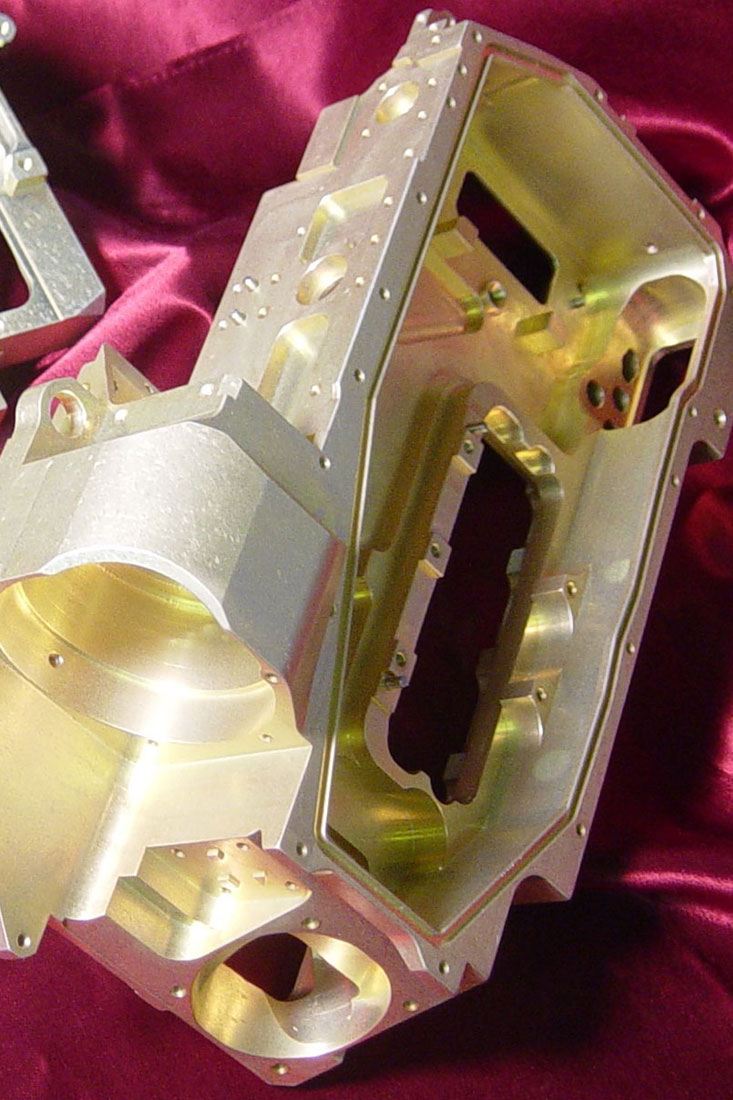

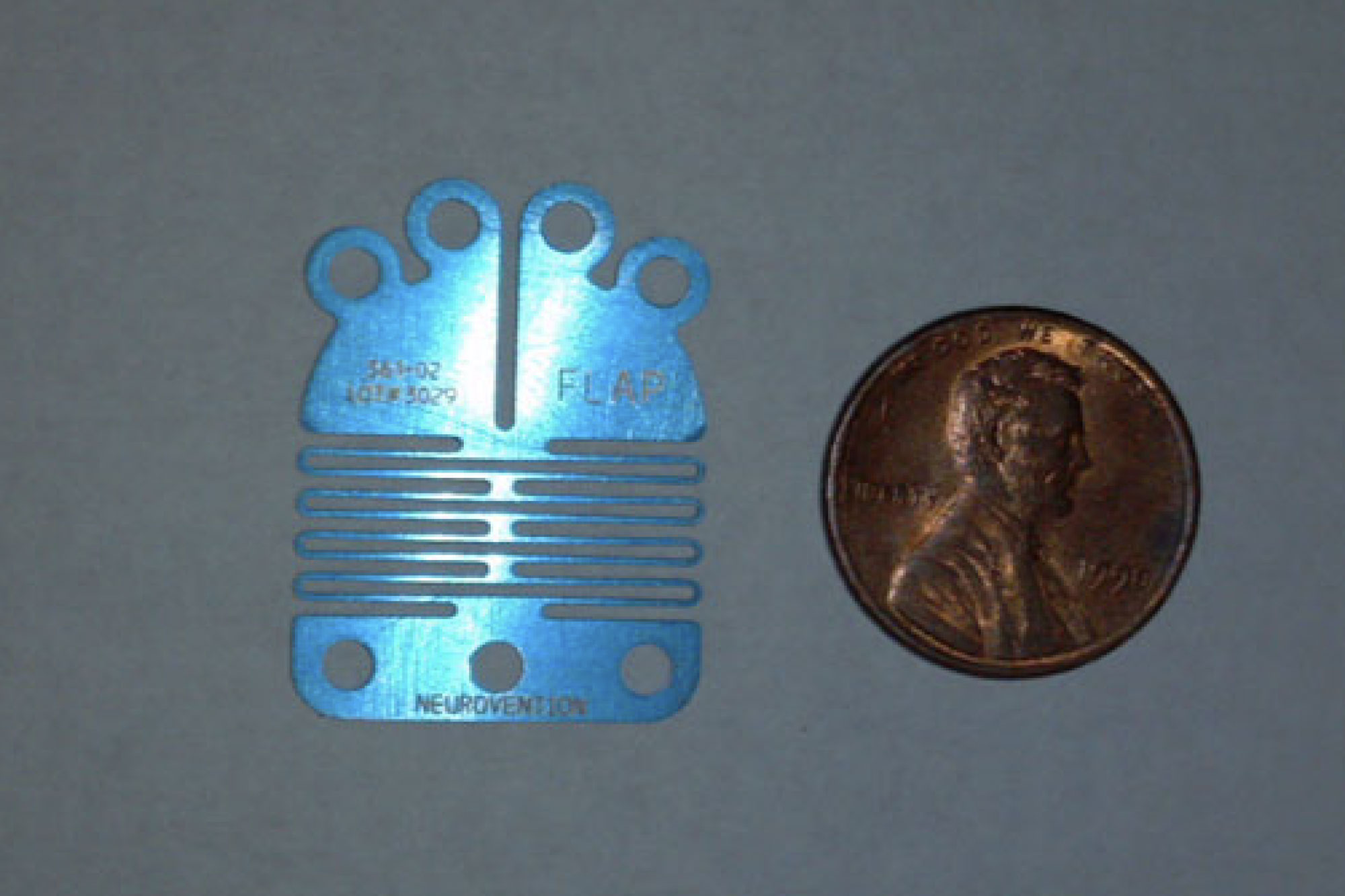

Beadblasting, Gritblasting, Vapor Honing operations for surface preparation. Deburring, tumbling, and edgebreak processes. Masking, mil spec wet paint and powdercoat, Chemfilm/Irridite/Chromate, anodizing and hardcoat plating, electroless nickel plating.

Plating solutions include:

JET HELSETH regularly processes parts with various plating operations including colored anodizing, hard coat anodizing, black oxide, black and yellow zinc, chemical film/yellow irridite, nickel, electroless nickel, and specialized processes such as armoloy and Teflon impregnated hard coat.

Thanks to everyone at JET Helseth Manufacturing, Inc. that helped bring our Ironman project together. Delivering ahead of schedule, with quality and improved our chances of closing this project with success.

I’m privileged to have a local facility such as JET Helseth Manufacturing, Inc., with their capacity and capabilities. Their professionalism, turnaround, fairness and ease to work with time have been exceptional.

Thank everyone for getting those parts to me so quickly. I know we’ve asked for miracles a lot in the past few weeks (last few years??), but you’ve ensured our success in this project.

JET HELSETH MANUFACTURING INC.

1730 Patterson Ave. Deland FL 32724

(407) 324-9001