MAJOR SHOP EQUIPMENT

Over 30,000+ square feet of manufacturing space with state of the art CNC machining equipment and QA equipment to meet the high demands of our clients.

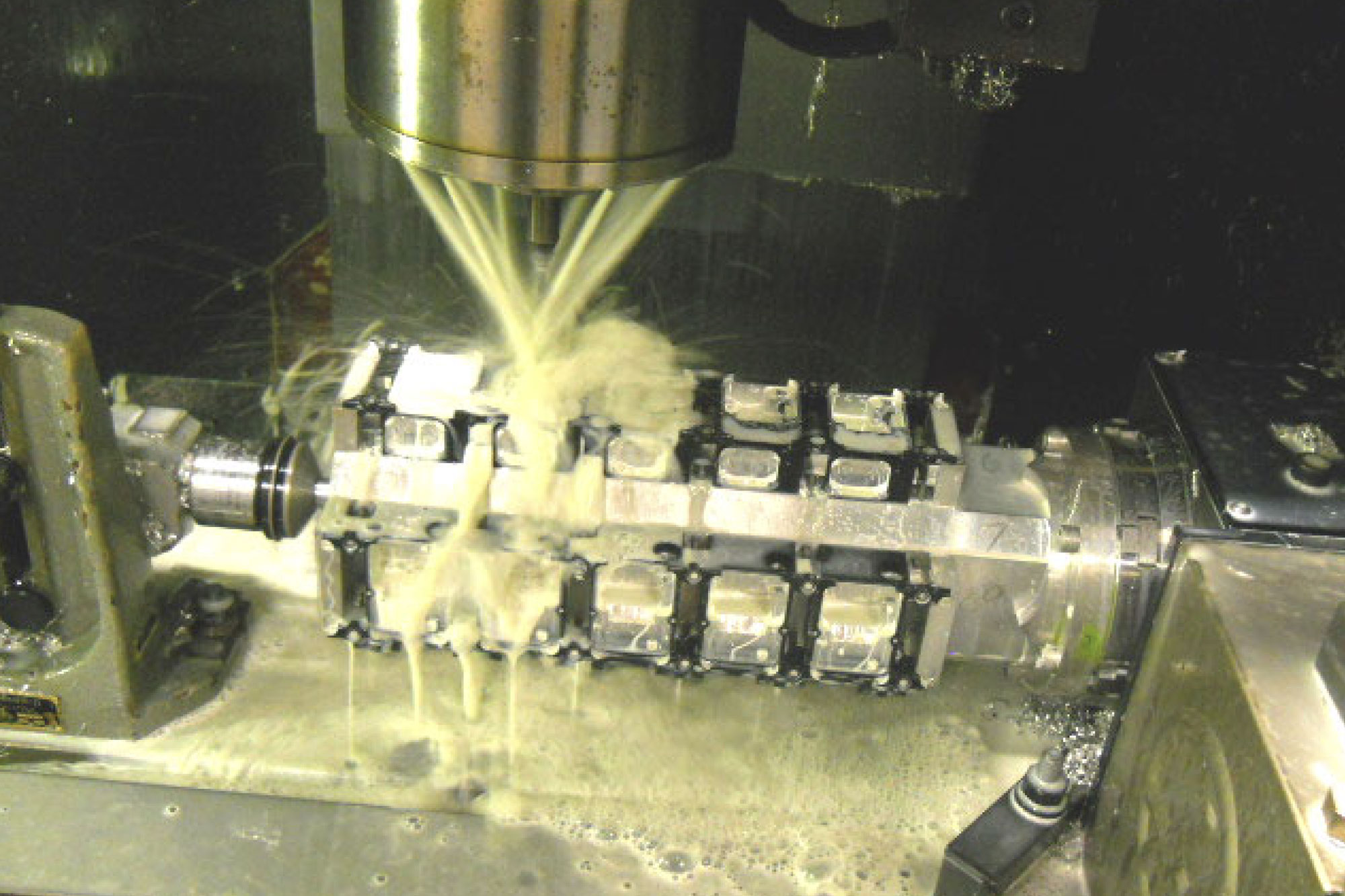

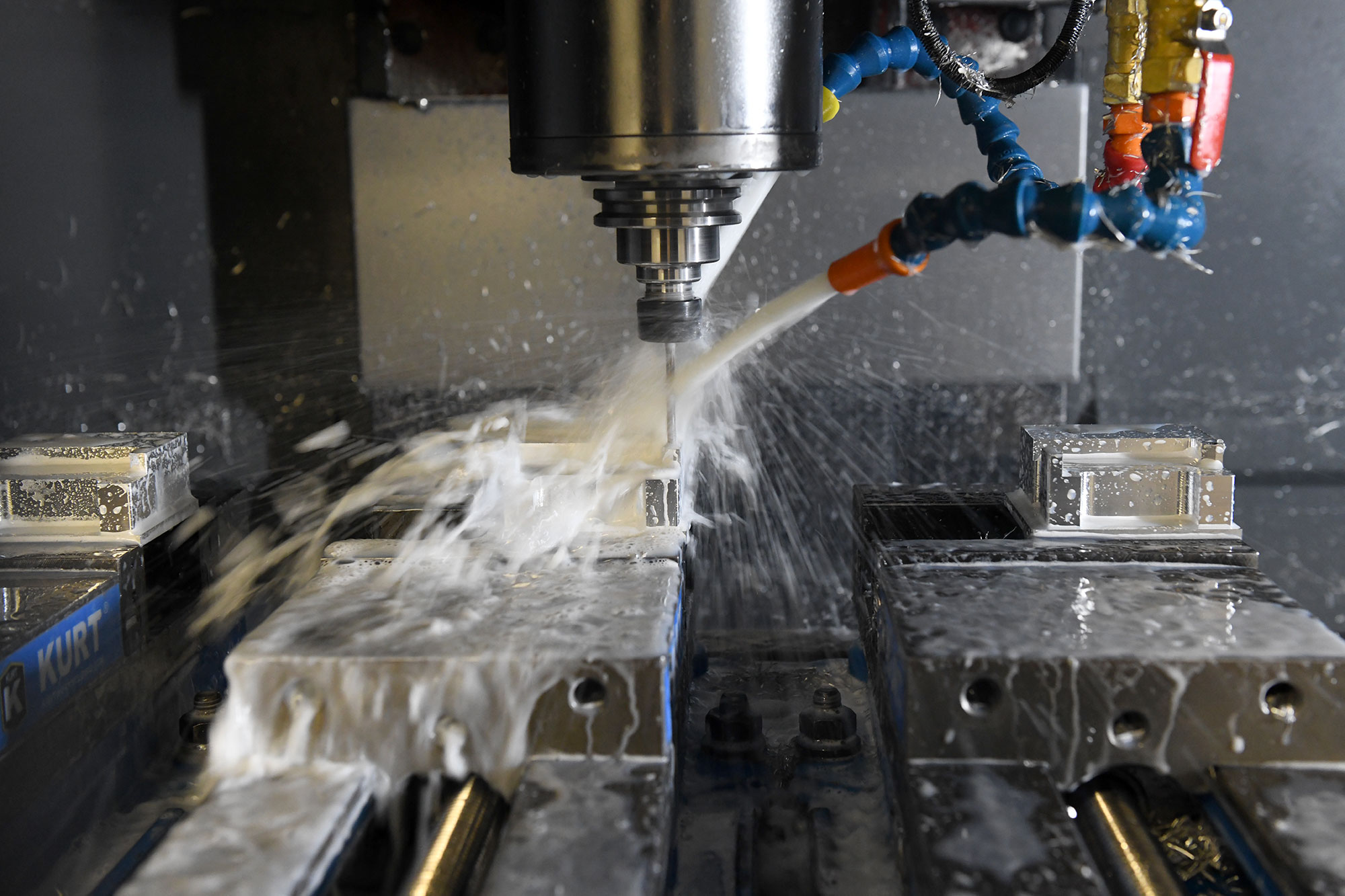

Jet Helseth Manufacturing CNC Equipment and Manufacturing Capabilities include 9 CNC vertical machining centers w/CNC rotary indexers, true 4th axis & 3D, Large 5 Axis machining Center, 7 CNC turning centers capacity up to 23” diameter, dual spindles, twin turret, live tools, OD/ID Cylindrical Grinding, 3 Axis Surface Grinder, 3 manual mills (vertical & horizontal), 3 manual lathes, horizontal saws, vertical saw, drill presses, tapping heads, arbor presses, assembly tables, electric and pneumatic Helical Insert installation tools, MIG & Tig welding, large and small parts tumbling machines, grit and bead blasting and polishing machines.

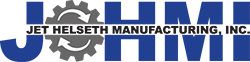

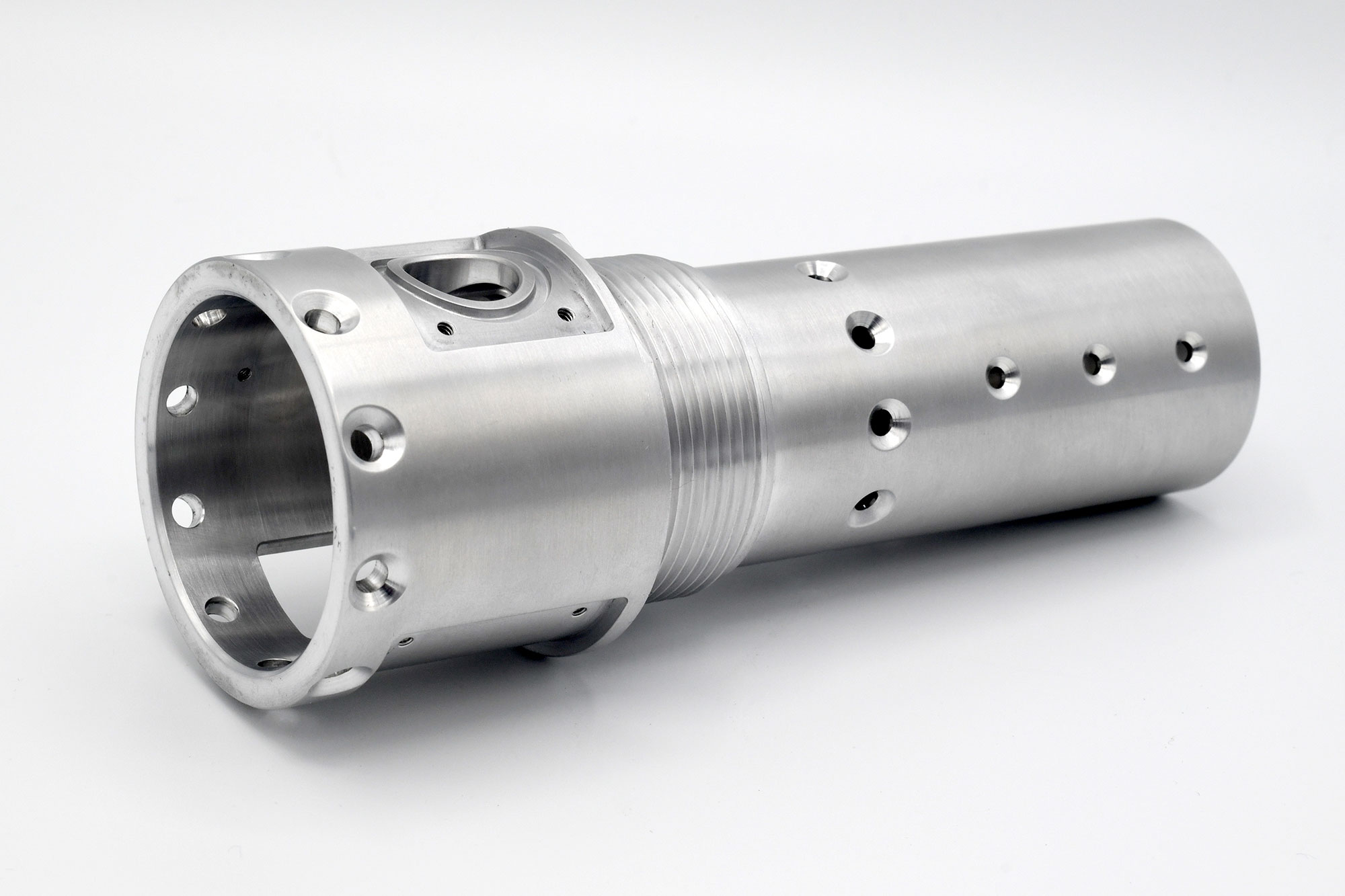

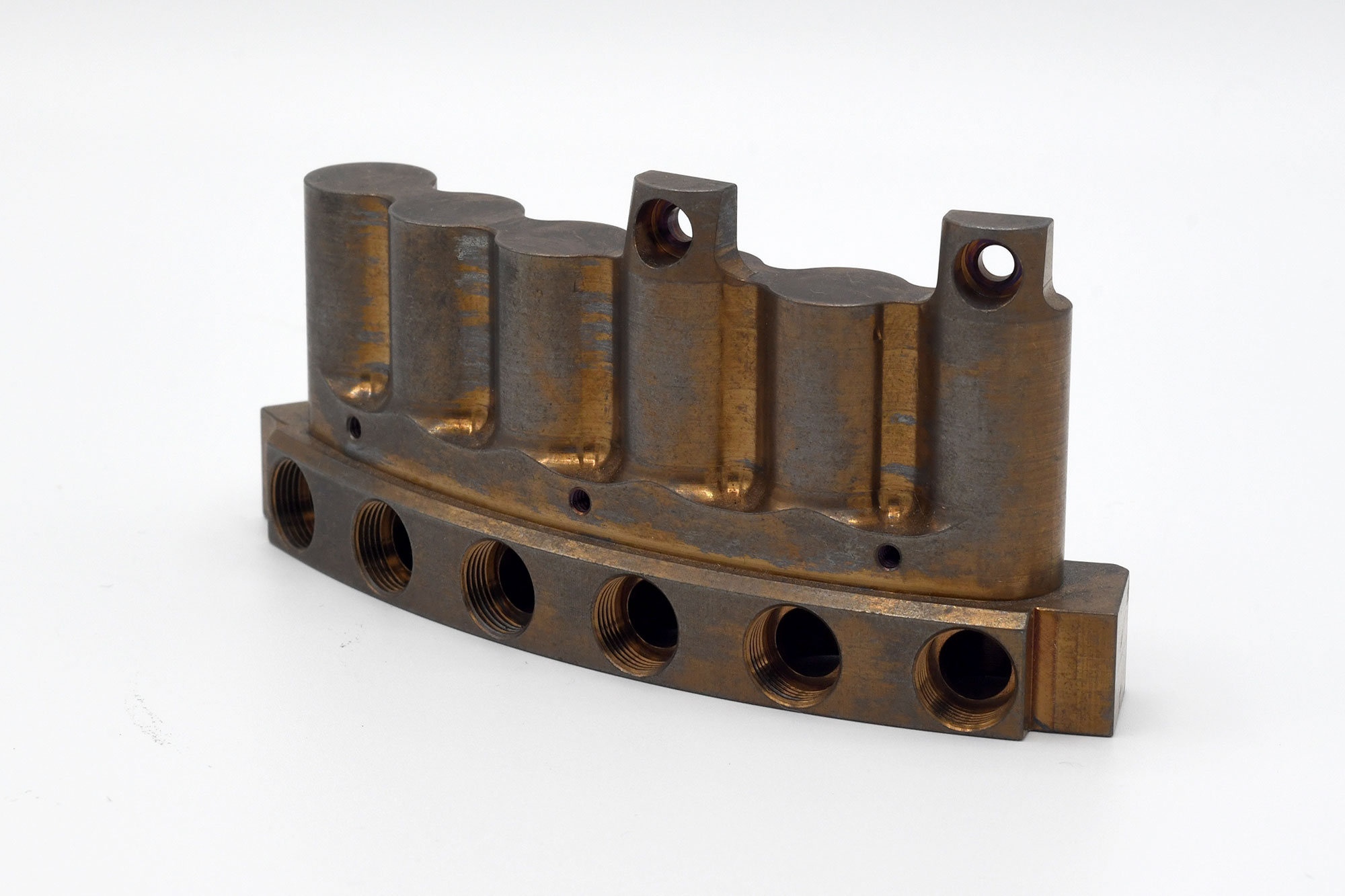

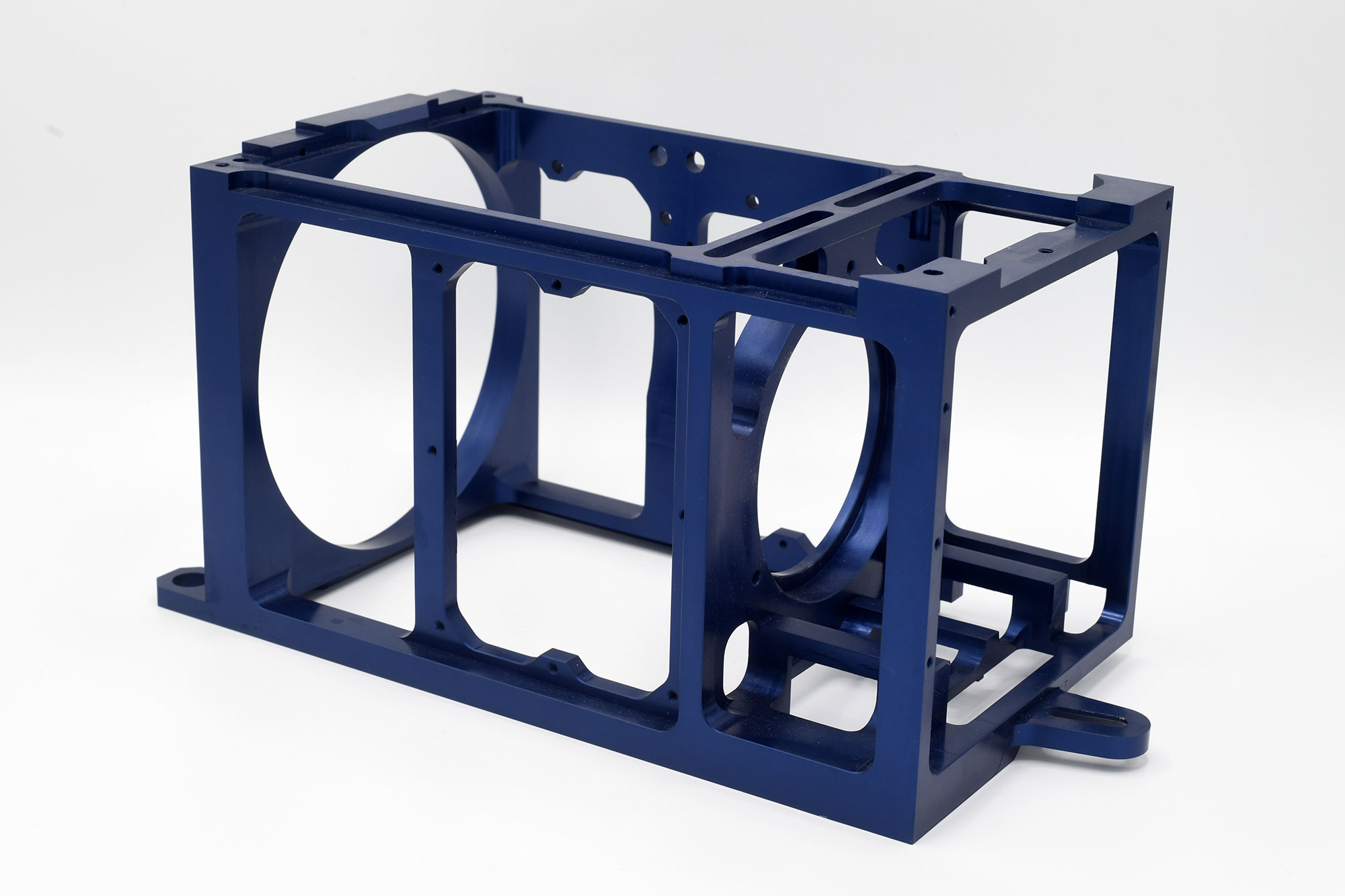

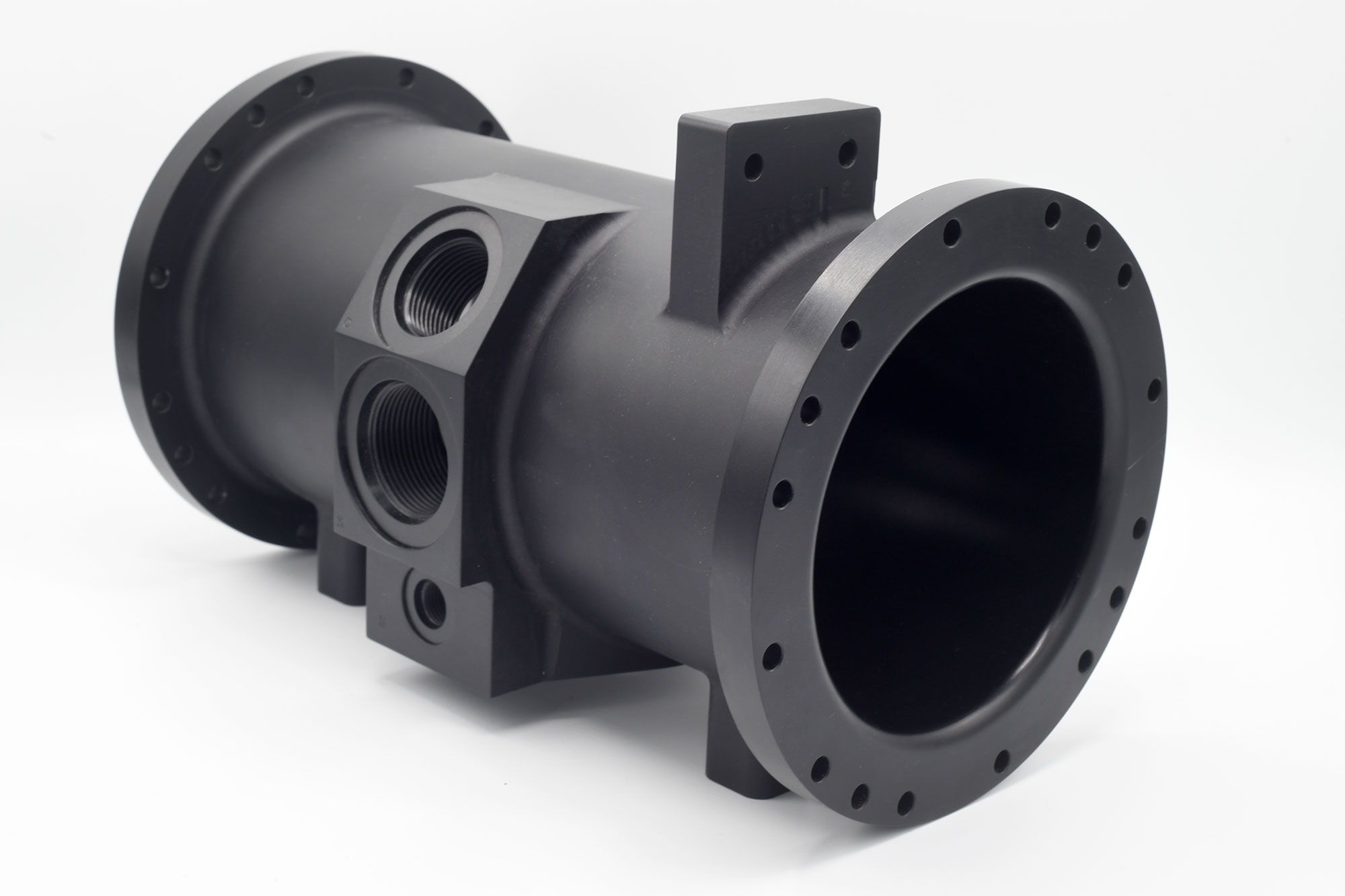

MULTI-AXIS MACHINING

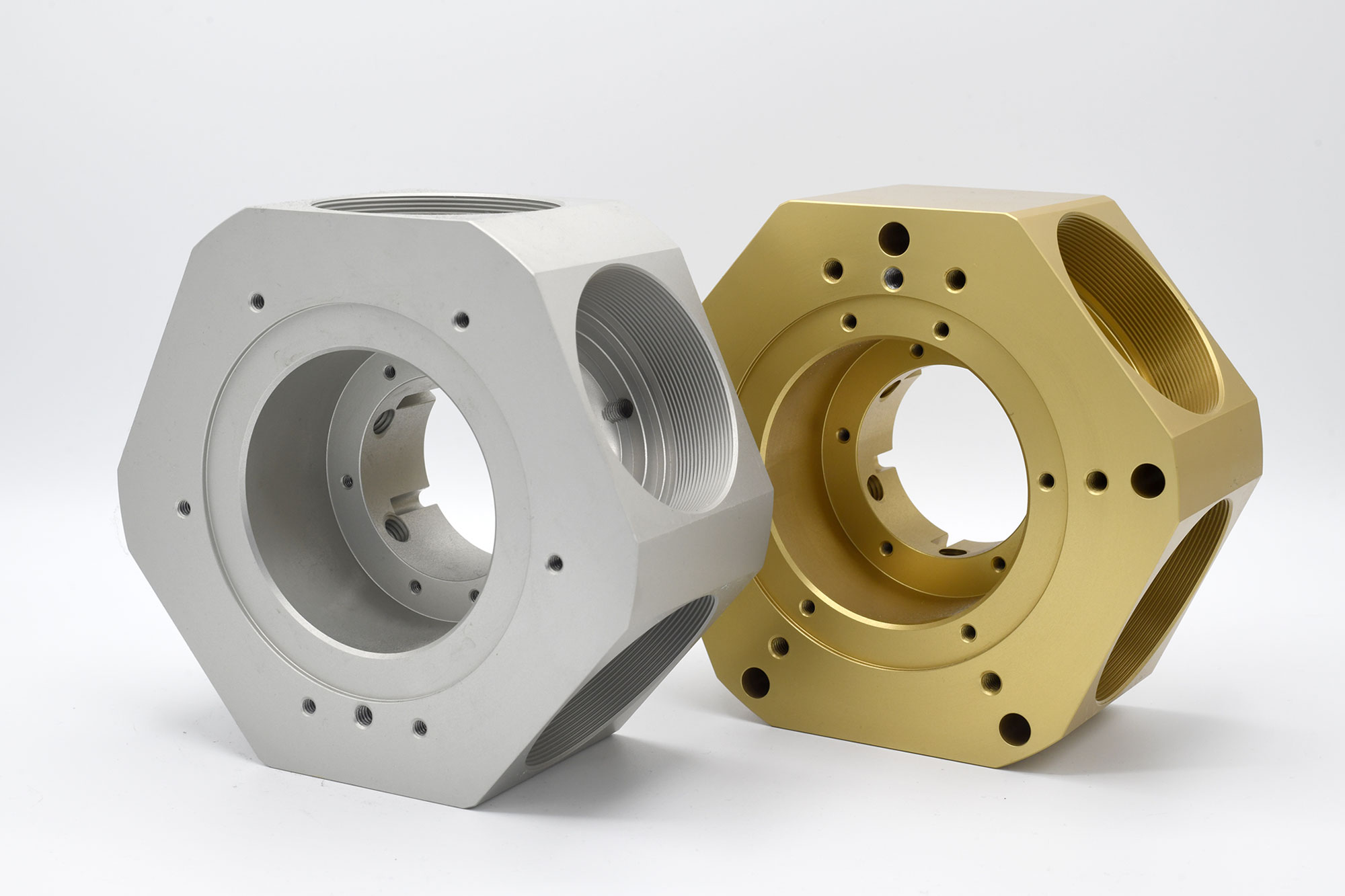

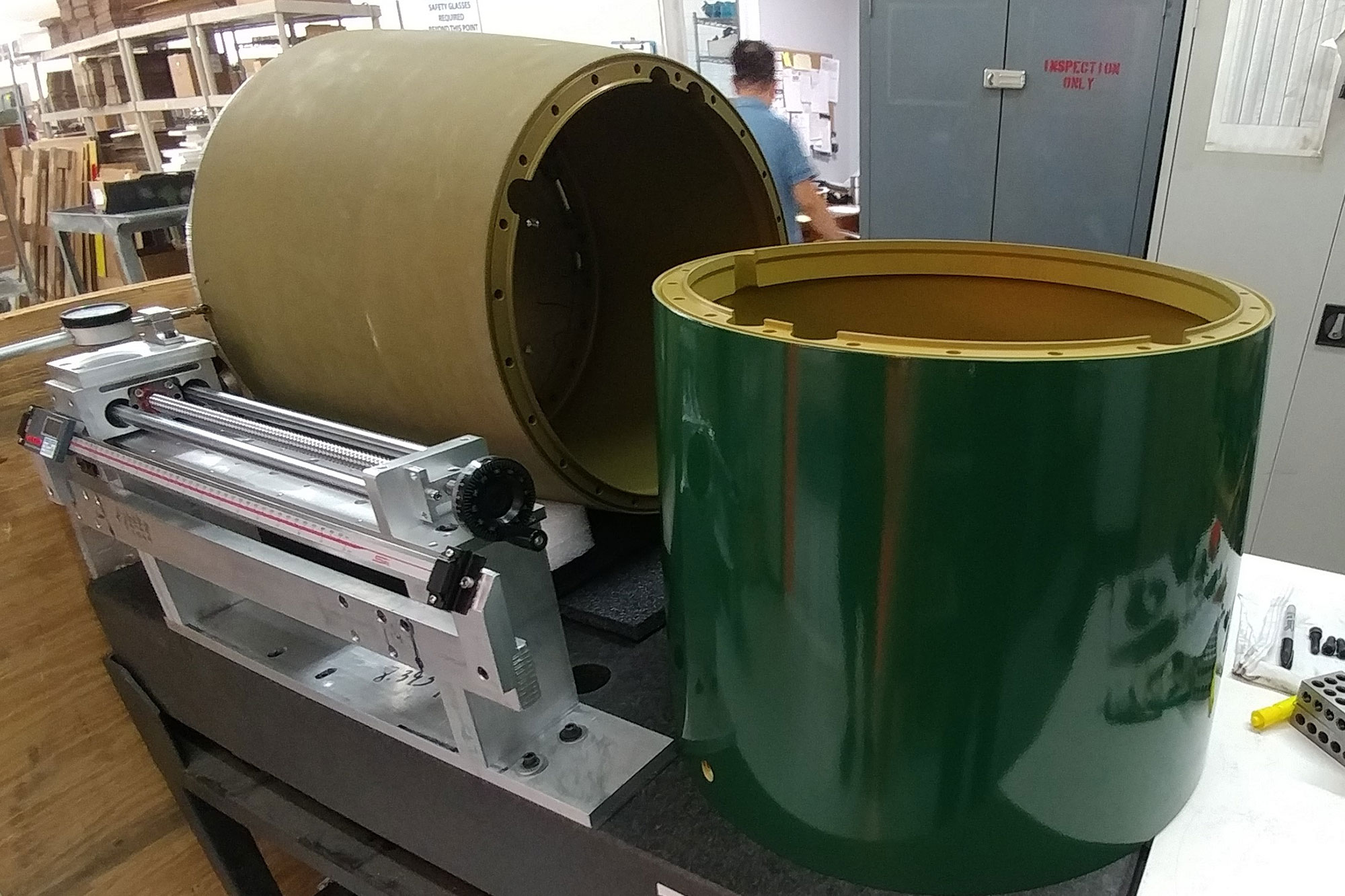

JET HELSETH specializes in multi-axis machining for components that require high degrees of precision and repeatability including 3-axis, 4-axis, 5-axis and 8-axis machining. We add the power of computer numerically controlled (CNC), computer aided manufacturing (CAM), and industry-leading software tools like Solidworks, Camworks, and Autocad to our decades of machining experience to produce parts and assemblies meeting or exceeding our customer’s expectations.

Our CNC machining specialists can program and oversee the production of highly complicated precision parts with the highest standards of quality, reproducibility, and safety in mind.

MULTI-AXIS EQUIPMENT

Featured in-house multi-axis machines are:

- Doosan Puma 8 Axis Twin spindle, twin turret CNC lathe

- Hurco 5 Axis Mill with Probe

- 9 – HURCO 4 Axis Vertical Machining Centers w/spindle chiller

- Hurco CNC Lathe, Live Tools

OTHER MAJOR CNC EQUIPMENT

CNC PRECISION MACHINING

Featured in-house precision CNC and specialty equipment:

- Takumi CNC Lathe

- Takisawa CNC Lathe

- Kia Turning Center 21 CNC Lathe, 2-axis SKT21B

- Hardinge CNC Turning Center, W/Tail Stock, Chip Conveyor, Tool Probe

- Nakamura-Tome Large CNC Lathe 22″ Diameter Capacity

- Chevalier 3 Axis Surface Grinder

- Covel I.D./O.D. Cylindrical Grinder

- Boyar-Schultz Tool Grinding Machine

- Vapor Hone System

- Dayton Bead Blast Cabinet

QUALITY ASSURANCE

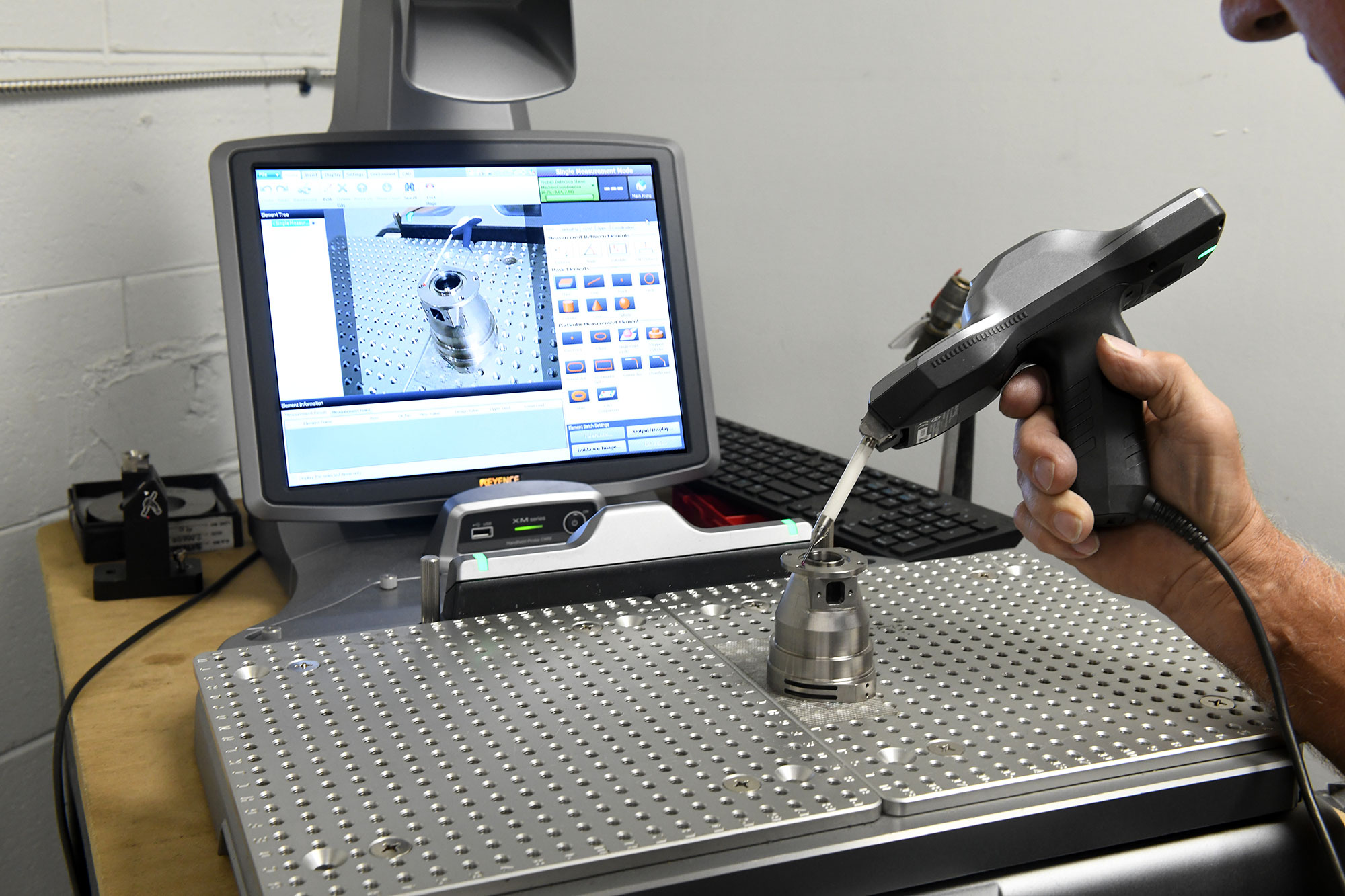

JET HELSETH has a fully staffed and equipped Quality Department with an ISO 9001:2015 system in place. First Article Inspection Reports to AS9102 Form Rev. B. Inspection equipment includes 4 ft x 6 ft Starrett surface plates and measurement indicating tools certified and traceable to NIST standards including height gages, gage blocks, micrometers, gage pins, large assortment of plug and ring gages, optical comparator, Supermic, B&S Mircro-hite, Faro Quantum ARM & Keyence CMM.

CNC EQUIPMENT FAQs

Here’s some of the most common questions about our CNC equipment and capabilities. For a full list of common questions visit our FAQ page. If you cannot find an answer to your question, please contact us with your question. We’ll be happy to assist you.

We typically run 2 shifts 5 days a week, and bring on additional shifts as needed to manage the production schedule.

Project lead times can vary widely depending on part complexity, surface treatments, etc., but mid line complexity parts can average 6-8 weeks delivery.

JET HELSTH Manufacturing machining capabilities are 3 axis, 4 axis, and 5 axis CNC Milling (machining centers), Multi-axis CNC Turning (lathes), and Grinding.

Yes, we have tumbling, bead blasting, grit blasting, and vapor honing machines to provide surface finish treatments, and we also have the metrology equipment to test and verify the finish level.

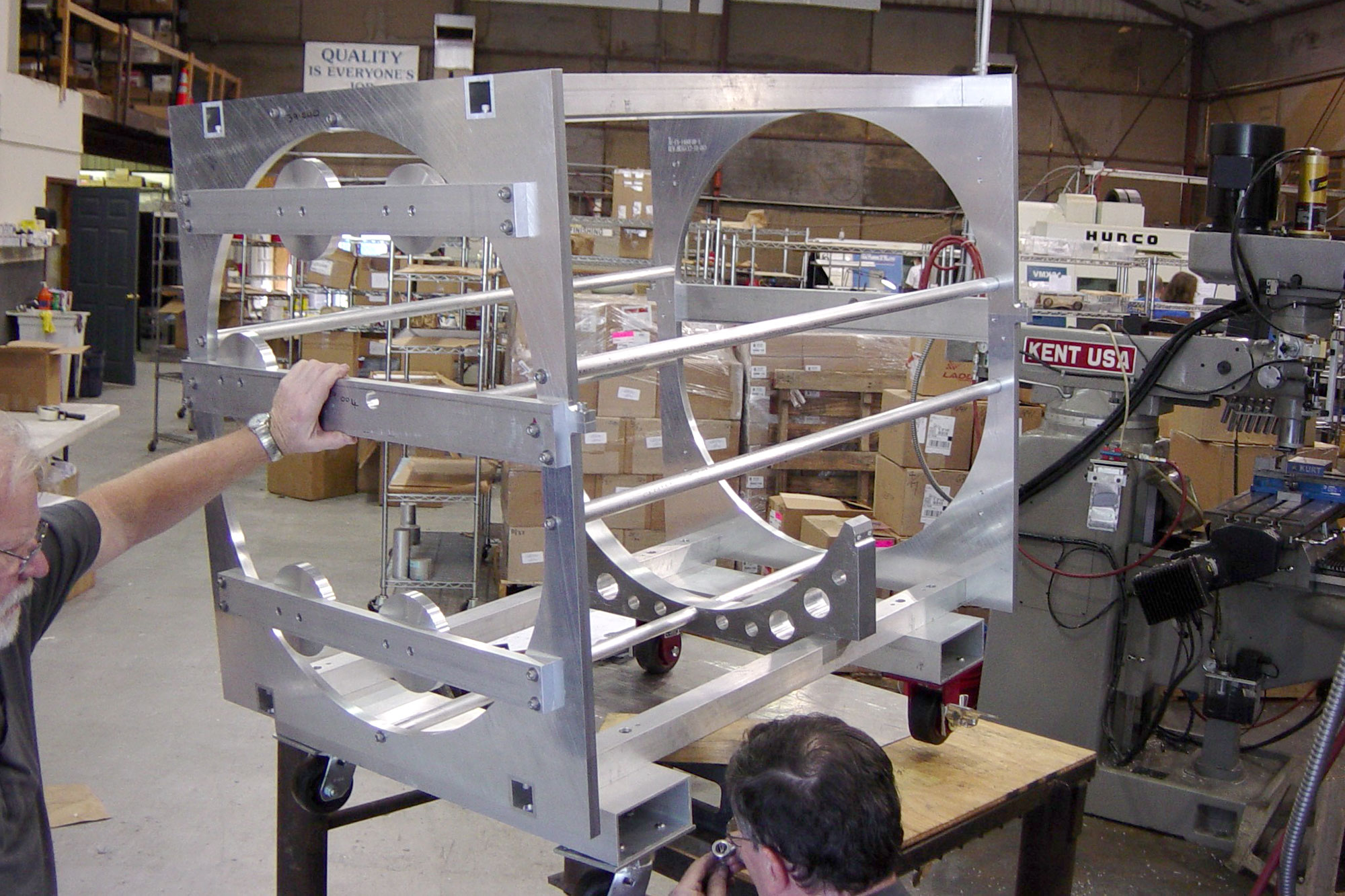

Yes, we can provide precision machined component parts, and also provide mechanical assembly of parts so that a customer can receive a single part number of a sub assembly of parts. We also can perform testing (force, load, pressure, and electromechanical) of parts and assemblies.

Yes, JET HELSETH does have mechanical and electromechanical engineering in house.

Yes, we are Lockheed certified to perform model based machining. We own Solidworks, Camworks, and Autocad. We typically work with the following drawing/model formats: Dimensioned drawings – .pdf, models in .dxf, .stp, .igs formats.

Yes, we have 2.

Yes, Passivation of Stainless steel, aluminum Anodizing, Hardcoat Anodizing, EN Nickel plating, Chemfilm (chromate conversion coating), Mil-spec wet paints, powder coating, and Cerracote to name a few.

JET HELSETH MANUFACTURING INC.

1730 Patterson Ave. Deland FL 32724

(407) 324-9001